MOLDINO - 4 flutes high efficiency ball end mill : EHHBE-TH3 | JSR GROUP

EHHBE-TH3

4 flutes high efficiency ball end mill

Evolved by addopting a TH3 Coating on 4-flute ball end mill for high hardened steel processing. On high-hardened steel processing, to achieve even longer tool life.

Features of EHHBE-TH3

1.Highly efficient cutting with 4 flutes

2.Special edge shape in tip area improves cutting performance.

3.TH3 Coating provides long tool life even on hardened steels.

4.Variable Pitch geometry enables vibrations to be suppressed even for 4 flutes.

5. Wide chip pocket improves chip removal

6. Available for adaptive milling.

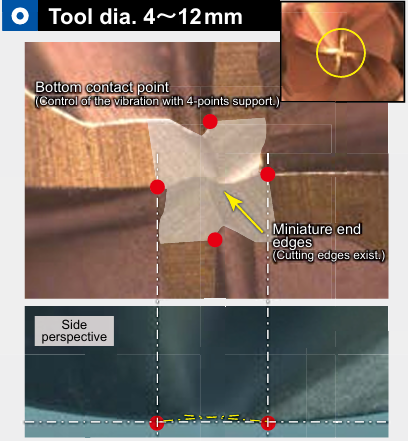

| Features | Special tip shape |

<Features and effects> <Features and effects> By creating a special flank face with a tiny relief angle at the very tip section, R accuracy is improved even with 4 flutes. |

<Features and effects> Features: Zero cutting point at the center is isolated from the cutting point. Effects: Chipping due to jamming of cutting chips at center ares is suppressed. |

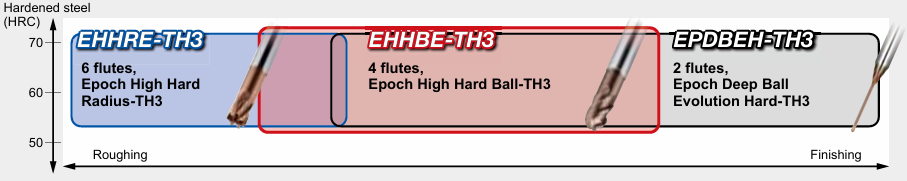

| Features | Performance and positioning |

|

EHHBE-TH3 exhibits the performance during roughing to semi-finishing of high hardened steel (55HRC~).

|

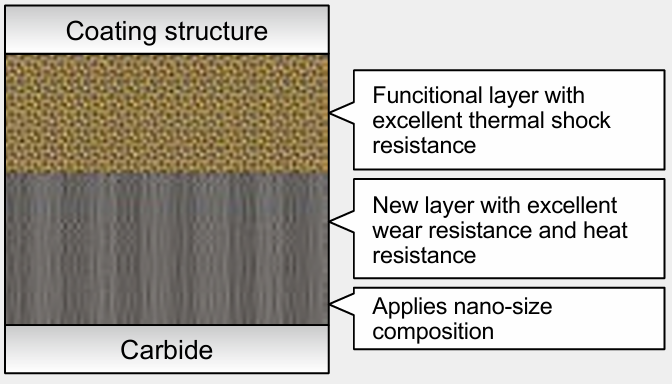

| Features | Newly developed "TH3" coating for hardened steel machining. |

| Features and performance |  |

|

| ・High hardness coating with excellent wear resistance and heat resistance ・Has excellent thermal shock resistance which reduces the risk of rapid tool chipping. ・Long tool life when cutting high-hardness materials (50HRC or higher) such as hardened steel |

||

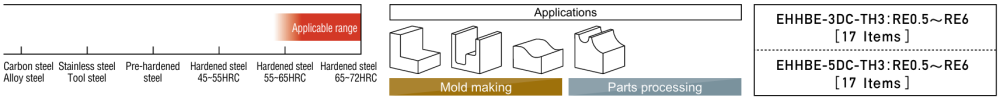

| Target steel grade | ||

| ・Hardened steel (especially 50HRC or higher), high-speed steel | ||

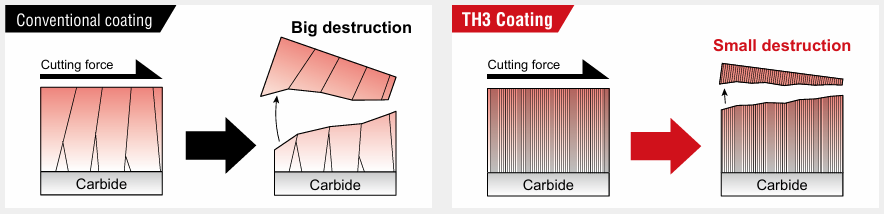

| Point | TH3 Coating achieves to reduce destruction unit of layer by applying "nano-size composition" | |

|

||